Visit at Polish greenhouses

Greenhouse production is an important part of vegetable sector in Poland. It is also the sector where the Dutch technology is a worldwide leader in technology and innovative solutions. The Embassy in Warsaw invited guests from the Netherlands for a conference dedicated to Polish tomato growers to present the best and sustainable solutions for this type of production offered by the Dutch companies.

But the guests were also eager to learn more about the current level of development of the Polish greenhouse sector. Therefore we invited them to show the Polish greenhouse production and we went with them for a one day trip. We visited three big Polish greenhouses:

- Baziółka with herb production,

- Nowalijka with hydroponic lettuce production and finally a

- Polish tomato grower.

All three visited greenhouses brought nice input in the knowledge of our speakers.

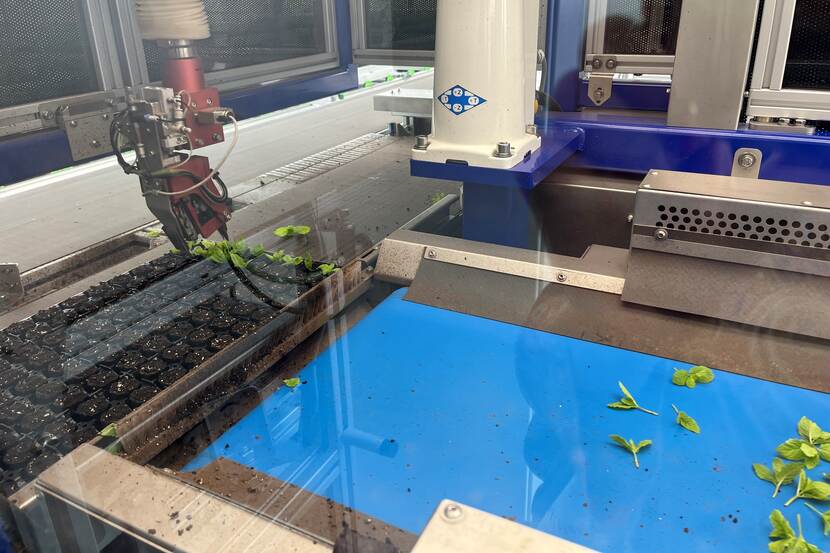

Plastic tunels and robot at Baziółka

Poland has around 5000ha production under cover. According to diverse measures up to 60% of the production occures in greenhouse tunnels.

At Baziółka our guests learned what a production tunnel actually means. With double layers and air pressed between the two, tunnels are a really good alternative for a regular greenhouse, with way less financial effort of the grower. Also there is a possibility to fully open the roof of it so in case of too much warmth inside the ventilation goes really smooth.

At the premisses there was also a possibility to check out the latest robot that was doing picking the young mint plants into pots used later for production process.

The whole greenhouse is surrounded by maize fields which is a challenge and natural check for the higine methods used at Baziółka. The company is selling their herbs to most of the Polish retail chains. Both as own brand or a private label of the retail chain.

The manager agreed that Baziółka is noticing a drop in sales of herbs produced in ecological way. Once the price of those products is higher and due to inflation rate Poles are very carefully picking their products into shopping trolleys. A second reason is the fact the the majority of them doesn’t see a big difference in herbs produced in a ecological way and in a regular way (‘both are grown in one greenhouse, next to each other.’).

Baziółka uses gas as a main source of energy and the company has a so called cogeneration furnace to produce their own energy.

At Baziółka company a robot is hired to recognize the plant stems (mint herb on the picture), picking them gently up and putting in the soil. The whole process is supervised on the computer behind the machine. The plant tops are visible for the camera as they are placed on the blue belt.

Nowalijka- from trade to production

The second company, Nowalijka, was initially operating only in trade, but the market forced the family to establish a greenhouse and start their own production. During the years they grew and now the production covers up to 60% of their profit and trade is responsible for 40%. The company has contracts with growers from the neigbourhood who produce their commodities for Nowalijka. The company re-sells them further to retailers or uses for own products like salades, soups and other ready to eat meals they also sell to retail chains.

They also presented nice diversity in the production: next to lettuce as a vegetable the company also offers ready to eat salads based on their own lettuce varieties that are also very interesting for their retail partners.

Next to that the company has some land and procuces there also berry- fruit like raspberries and blueberries. They sell those products to their trade partners as well.

Floriańczyk

A very unique opportunity was the visit at the Polish tomato grower, mr Floriańczyk. In his two greenhouses he grows only a so-called pink tomato, that is desired on the Polish market.

As the variety he's is using is still not ToBRFV proof, it was a rare possibility to get into the greenhouse. Mr. Floriańczyk is using biological protection for his tomatoes, and sells them to the biggest Polish retail chain- Biedronka.

He drew the attention of the group for the small sticky labels that have to be put on every produced tomato. He’s now thinking about the possibility to remove it from the fruit, as it is only additional plastic without any added value.

The companies had a different profile or technology than this what is common in the Netherlands. Therefore before the promotion of own technology it is good to visit some Polish companies and check the current level of solutions.

This might be a very good trip!

Source: LAN-team Warsaw